Cyclic Corrosion Testing

Cyclic Corrosion Testing is much like Salt Spray Testing, in that it is an accelerated corrosion test, used in the evaluation of coatings and surface treatments. Salt spray testing evaluates a coating or surface treatments ability to resist corrosion. While cyclic corrosion testing does the same thing, it also evaluates its ability to withstand changes in various environmental influences such as temperature & humidity.

Cyclic corrosion testing is particularly useful for detecting discontinuities, such as pores and other defects, in certain metallic, organic, anodic oxide and conversion coatings. Giving an indication to a coating or finish’s ability to resist corrosion during its life in service.

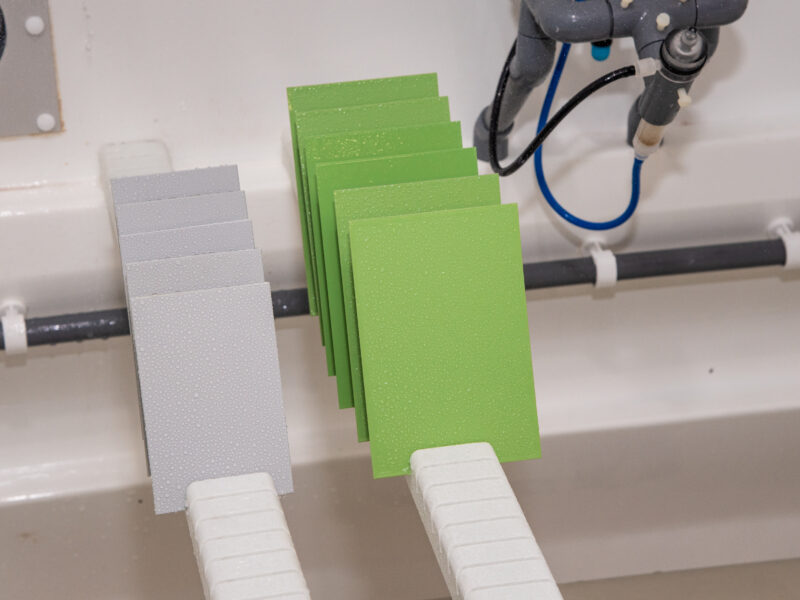

Cyclic Testing on Coated Samples

- Cyclic corrosion testing can be a useful tool for evaluating finishes such as paint, powder coatings & e-coatings. Where prior to exposure defects can be introduced in the form of scribe lines & evaluated for undesirable defects such as delamination & filiform corrosion, methods include:

- ISO 4628-8 Assessment of degree of delamination and corrosion around a scribe or other artificial defect.

- ISO 4628-10 Assessment of degree of filiform corrosion.

Evaluations remote from a scribe mark can include:

- ISO 4628-2 Assessment of degree of blistering.

- ISO 4628-3 Assessment of degree of rusting.

- ISO 4628-4 Assessment of degree of cracking.

- ISO 4628-5 Assessment of degree of flaking.

- ISO 4628-6 Assessment of degree of chalking by tape method.

Cyclic Conditioning

Cyclic corrosion testing can be used as a preliminary exposure to other testing. Where the cyclic exposure aspect is used to artificially age the coating or finish & the post exposure test evaluates performance capabilities to assess appropriate application for its intended purpose. Common post exposure testing include:

- ISO 1518 Determination of scratch resistance.

- ISO 15184 Determination of film hardness by pencil test.

- ISO 6272 / ASTM D2794 rapid deformation by impact.

- ISO 2409 Paints and varnishes — Cross-cut test.

Cyclic Tests

There are an infinite number of cyclic corrosion exposure ranging from the very basic to the very complex requiring fully automated chambers. The principles remain the same. Specimens are exposed to various environmental conditions in an outlined cyclic fashion. Some specifications allow the transfer of specimens between cabinets offering the required environment. The more complex specifications dictate fully automated chambers, where it would not be reasonable to fulfil the cycle manually. The duration of exposure is dictated by relevant standard/specification or the customers bespoke requirements. Quantitative & qualitative evaluation can be made at regular intervals during testing & on completion of the entire exposure period. Common evaluation methods of inorganic coatings on metallic substrates include:

- ASTM G46 examination & evaluation of pitting corrosion.

- ISO 10289 method for corrosion testing of metallic and other inorganic coatings on metallic substrates – rating of test specimens and manufactured articles subjected to corrosion tests.

Equipment

Aerofin Laboratories are proud to offer cyclic testing using Ascott analytical chambers including the Atmosfär chamber. Atmosfär chambers have been specifically designed for fully automatic testing in accordance with highly demanding laboratory-accelerated corrosion tests which have become increasingly popular in some sectors of the automotive industry.

These tests are cyclic in nature and comprise of exposure under controlled and varying conditions of temperature and humidity, with intermittent spraying of a salt solution directly on to the samples under test, from a high level swaying spray bar.

- Popular Atmosfar Test Standards:

- FORD CETP00.00-L-467

- ISO 16701

- Scania STD 4319

- Scania STD 4445

- TPJLR.52.265

- Volvo STD 1027,1375

- Volvo STD 1027,14

- Volvo STD 423-0014

- Volvo STD 4233

Capacity

- Testing of large components or assemblies? Aerofin’s current maximum capacity is facilitated utilising the Atmosfär AT2600iP, with a 2600 litre chamber capacity.

- Large test schemes? With a total of over 12,000 litres of test chamber availability, Aerofin are able to offer rapid response for urgent testing requirements.

For information on cyclic chambers visit https://www.ascott-analytical.com/