Heat Treatment Metallurgy.

The primary objective of metallographic examinations is to reveal the constituents and structure of metals and their alloys by means of a light optical microscope.

The proper selection and preparation of the specimen is of major importance in obtaining reliable results. in most cases this means cutting, mounting & polishing. This must be performed in such a manner as not to introduce any unwanted morphologies in the process. We therefore follow the guidance of ASTM E3 Standard guidance for preparation of metallographic specimens.

Alpha Case & Heat Affected Zone

Titanium has low oxidation resistance when exposed for long periods in elevated temperatures containing oxygen. When exposed to these conditions titanium reacts with oxygen forming an oxide scale on the surface of the material. Beneath this oxide scale a hard and brittle oxygen enriched layer is produced known as Alpha Case.

Alpha Case reduces the mechanical properties of titanium. Decreasing ductility, fracture toughness and fatigue life.

Heat Affected Zone (HAZ) is an area that didn’t melt during cutting/welding, but has had its micro structural and mechanical properties altered as a result of the exposure to heat. Heat Affected Zone will be evident at the weld/cut interface where its size can vary depending on factors including: exposure time, temperature and material type.

Changes in micro structure in the Heat Affected Zone cause stresses that reduces the strength of the material. High-temperature exposure and welding can significantly affect the micro structure and properties of the heat-affected zone that makes them more susceptible to corrosion.

Test Methods include:

- BSEN 2003 – 009

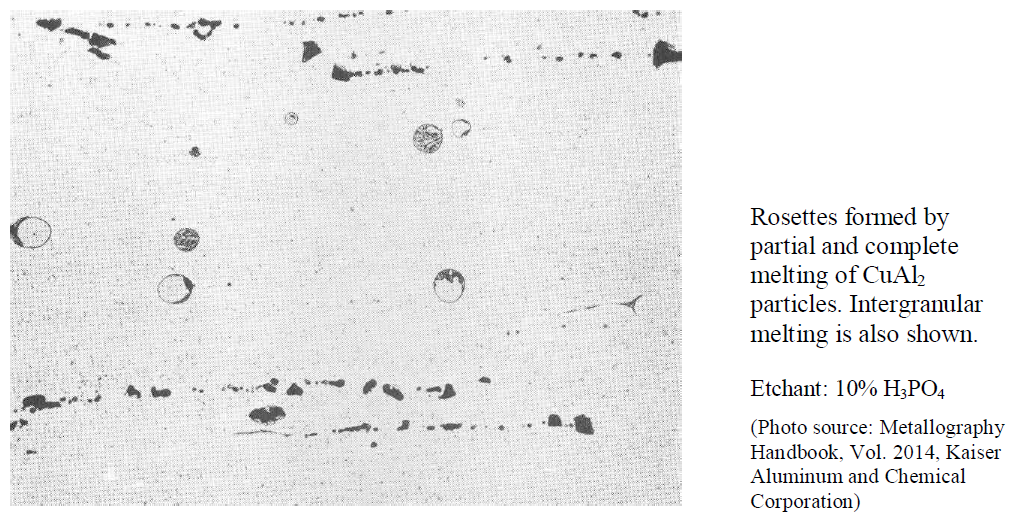

Eutectic Melting

Eutectic melting is the localised melting of the low melting eutectic composition in some alloys as a result of heat treatment. Eutectic melting causes a significant loss in ductility and resistance to fatigue cracking as a result.

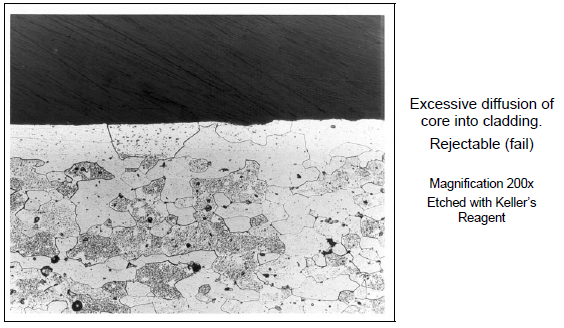

Diffusion Into Cladding

Corrosion protection in the form of cladding is susceptible to core diffusion into cladding during heat treatment processes. At high temperatures the solubility of copper and magnesium is enough to generate the risk of these elements diffusing from the core into the cladding.

Diffusion of these elements into the cladding reduces the electrochemical potential between the cladding and the core, such that the cladding no longer acts as protection against corrosion.

High Temperature Oxidation

High Temperature Oxidation (HTO) can lead to the deterioration of aluminium and its properties. High Temperature Oxidation is the diffusion of hydrogen at the materials surface at high temperatures.

At elevated temperatures contaminants such as sulfur decompose aluminium’s natural protective oxide layer. When this happens in the presence of moisture, hydrogen is diffused into the surface causing a corrosion blister.