Paints & Varnishes Time to Dry Determination

Aerofin continues to add to our paint testing capabilities.

The drying time of a coating is significant in determining when a freshly painted room, floor or stairway may be put back in use or when a freshly coated article may be handled or packaged. Slow drying might result in dirt pick-up or, on an exterior surface, moisture might cause a non-uniform appearance.

Using a mechanical recorder, testing (described in ISO 9117) is used to determine the various stages of drying or curing in the dry-film formation of organic coatings for the purpose of comparing types of coating or ingredient changes, or both.

Using a mechanical recorder, testing (described in ISO 9117) is used to determine the various stages of drying or curing in the dry-film formation of organic coatings for the purpose of comparing types of coating or ingredient changes, or both.

The stages of drying are evaluated in a quantitative manner and are undertaken in controlled environmental conditions using a mechanical recorder . The use of a mechanical recorder also offers a method of determining the drying characteristics of coatings that cannot be ascertained within the standard 8 hour working day. Drying time testing is also useful in comparing the behaviour during drying of coatings of the same generic type.

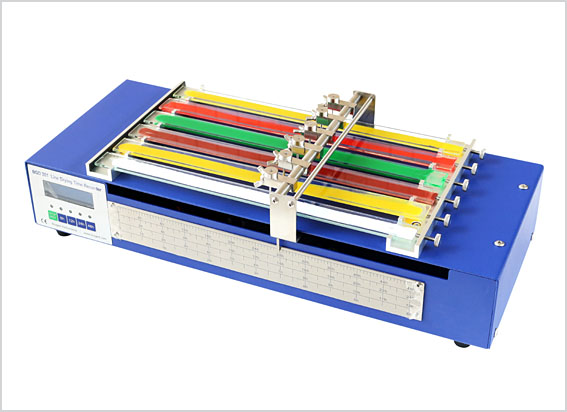

Aerofin uses an Ascott Standard Line Drying Time Recorder for our testing.

The Standard Line Drying Time Recorder (T01-700601) is a versatile piece of equipment. It can quantify the various stages of film curing and drying, and deliver reproducible results. The Recorder is designed to test the drying time or gelation behaviour of many paints and coatings. The coating is applied onto a glass strip of 330mm×24mm by means of a cube applicator (T01-700036/37). Needles travel in a hemispherical manner on these test tracks, over a selected time of 6h, 12h, 24h or 48h. The drying time stages can be easily assessed with the graduation scale (according to traverse speed configuration). The unit has an LCD Screen where the total time for every test can be observed.

The Standard Line Drying Time Recorder (T01-700601) is a versatile piece of equipment. It can quantify the various stages of film curing and drying, and deliver reproducible results. The Recorder is designed to test the drying time or gelation behaviour of many paints and coatings. The coating is applied onto a glass strip of 330mm×24mm by means of a cube applicator (T01-700036/37). Needles travel in a hemispherical manner on these test tracks, over a selected time of 6h, 12h, 24h or 48h. The drying time stages can be easily assessed with the graduation scale (according to traverse speed configuration). The unit has an LCD Screen where the total time for every test can be observed.